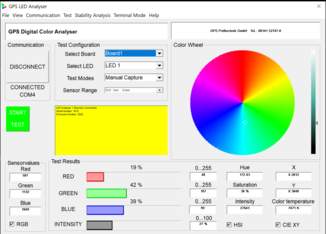

LED Analyser

LED Test

The Digital Color Analyzer is a color measurement system that allows fast and automatic testing of both the color and intensity of light emitting diodes (LEDs). Tests the full spectrum of visible light from very dim to the brightest LEDs on the market today. The new digital color sensor allows unmatched repeatability in testing color and intensity.

Application

- Testing LEDs on circuit boards

- Automotive - dashboard / brake lights

- Daylight as well as interior lighting of cars

- Switches with LED backlighting

- Mobile applications, backlighting and cell phones

- Industrial and medical technology

- Display elements

- LED interior lighting

Specifications

- Designed for a wide range of test applications

- Tests the full spectrum of visible light from LEDs

- Intensity testing from very dim to the brightest LED

- Excellent repeatability for color and intensity

- 5 channels available

- Allows up to 495 LEDs to be tested simultaneously

- Designed for testing colored and white LEDs

- Testing of two and three color LEDs

- RS 232 and USB interface

- Uses flexible plastic fiber optics for easy installation

Technical data

- External dimensions: 70x65x35 mm ( WxLxH)

- Length of the light guide: 600mm

- diameter of the light guide: 1,00mm or 2,20mm

- Number of light guides: 5

- Smallest radius of the light guide: 10mm

- Temperature range: 0C° to 50C°

Electrical data

- Operating voltage: 5.0 V

- Current consumption: 80 mA

- Interface: RS232 (Serial) / USB interface

Optical data

- Wavelength red (peak): 615 nm ± 3 nm

- Wavelength green (peak): 540 nm ± 4 nm

- Wavelength blue (peak): 465 nm ± 3 nm

- Total wavelength range: 450 nm to 650 nm for all colors

Sensor accuracy

- Standard chromaticity coordinates x, y (CIE 1931): ± 0.01 at x= 0.31 ; y= 0.35 at x= 0.35 ; y= 0.38 at x= 0.46 ; y= 0.43

- Dominant wavelength: 550nm ± 5 nm

- Color temperature CCT: 2856 °K ± 200°K

Reproducibility

- Standard chromaticity coordinates x, y (CIE 1931): ± 0,0015

- Dominant wavelength: ± 1 nm

- Color temperature CCT: 2.856 °K ± 50°K

- Hue: < 1%

- Saturation: < 1%

- Intensity: < 1%

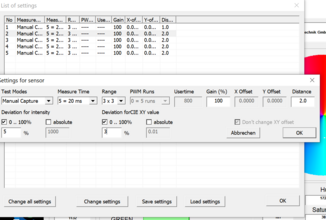

The LED Analyzer can be integrated into an existing test system by initializing the com port. In this application an offset can be stored for each LED to be measured. The operator can store an offset via the supplied GPS LED Analyser software. This is a volatile storage, which will be deleted after power off or a "Reset Board" command in the software. When restarting the LED Analyzer, the corresponding offset can be loaded at any time by reading in the test program.

Technical data

User manual

Detailed user manual is available in the PDF below.

LED_Analyser_Install.EXE

Program installation via following .EXE