Project & references

Customized, special solutions - Get an impression of our expertise

The design and implementation isn´t a standard solution. The test fixture has been developed and designed to meet specific customer specifications and requirements.

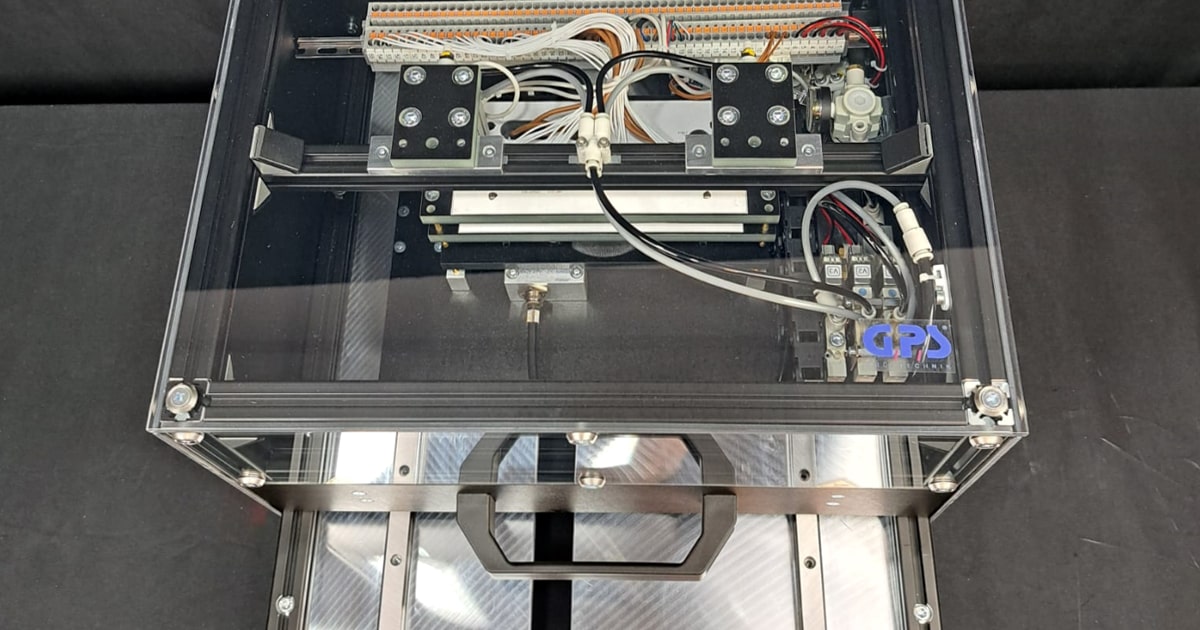

This test fixture is based on a multifunctional housing MFG-530 including a housing extension of 90 mm. The customized design includes different options for carrying out functional tests (FKT/FCT) and an LED test (DCA). The fixture has two…

This customized fixture is the model MFG-50-6100-TSI. The vacuum fixture has a multifunctional housing and in this case is equipped with a pylon interface. This type of housing offers maximum flexibility. Almost all interface types are possible here.

A special design whose construction and implementation was realized far from any standard solutions. The test fixture has been developed to meet specific customer specifications and requirements. The measurements are carried out in the high current…

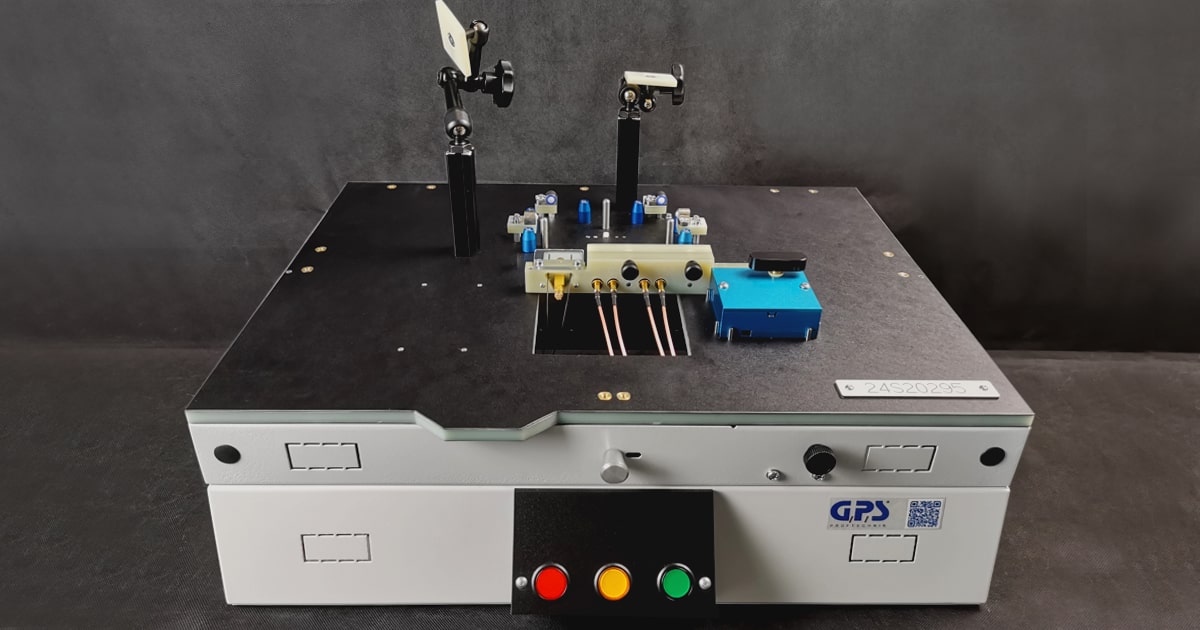

The WA-P-3000 is a pneumatic test fixture including an interchangeable kit that can be flexibly customized to meet specific requirements. In this case, a functional test (FCT) is carried out with a high output. The usable area is optimally utilized…

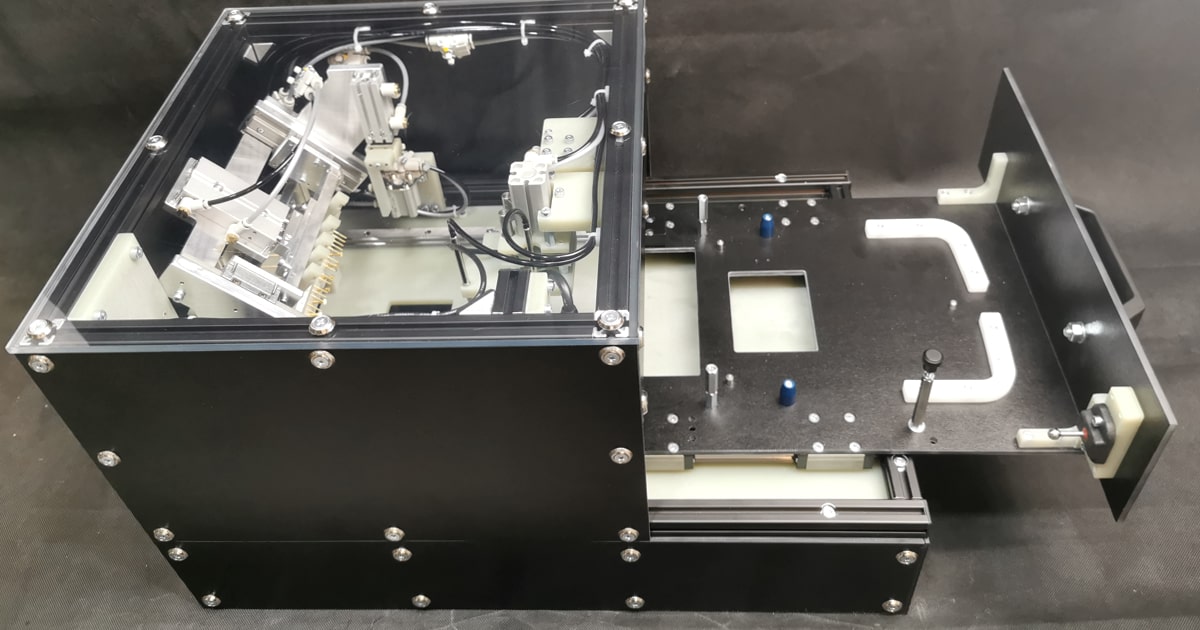

Vacuum test fixtures are suitable for contacting electronic assemblies with a high throughput of test specimens. In this case, it is a vacuum multifunctional system, a combination of housing incl. test system interface and an exchangeable set…

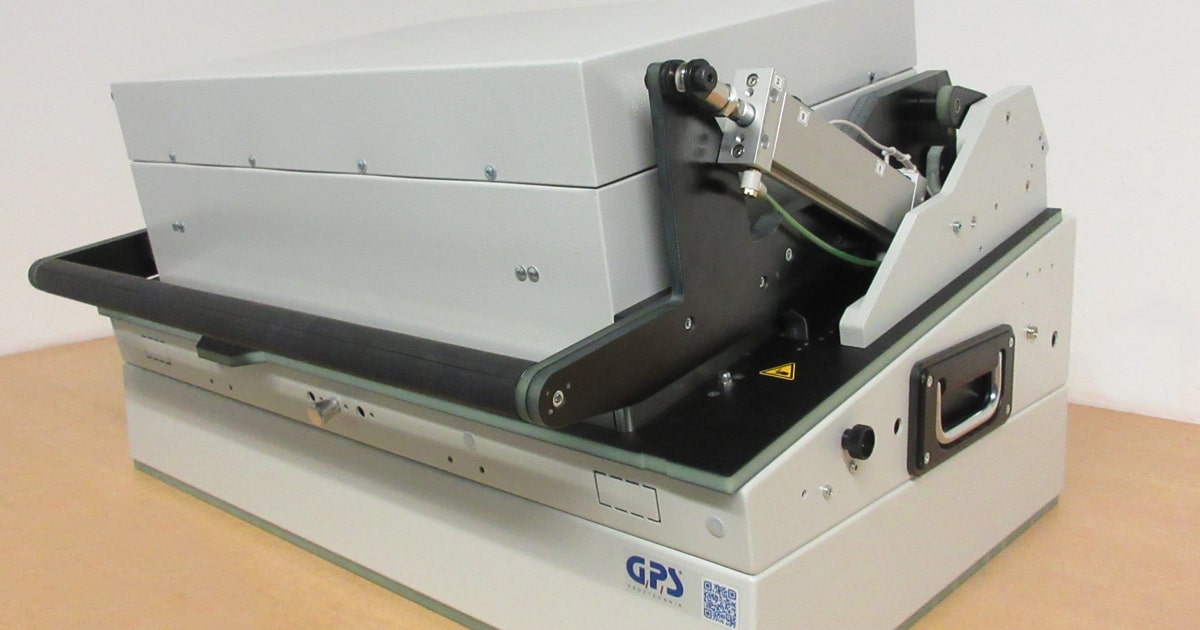

This type of test fixture is used for interference-free testing of high-frequency signals, with shielding attenuation being achieved in the frequency range of 6 GHz. This project involves a customized WA-HF-8000 with pneumatic start-up mechanism.

In addition to the customization of our own product lines, we have extensive expertise in customizing test fixture kits and interchangeable kits from other manufacturers. This is a pure customization project. A mechanical test fixture for bi-level…

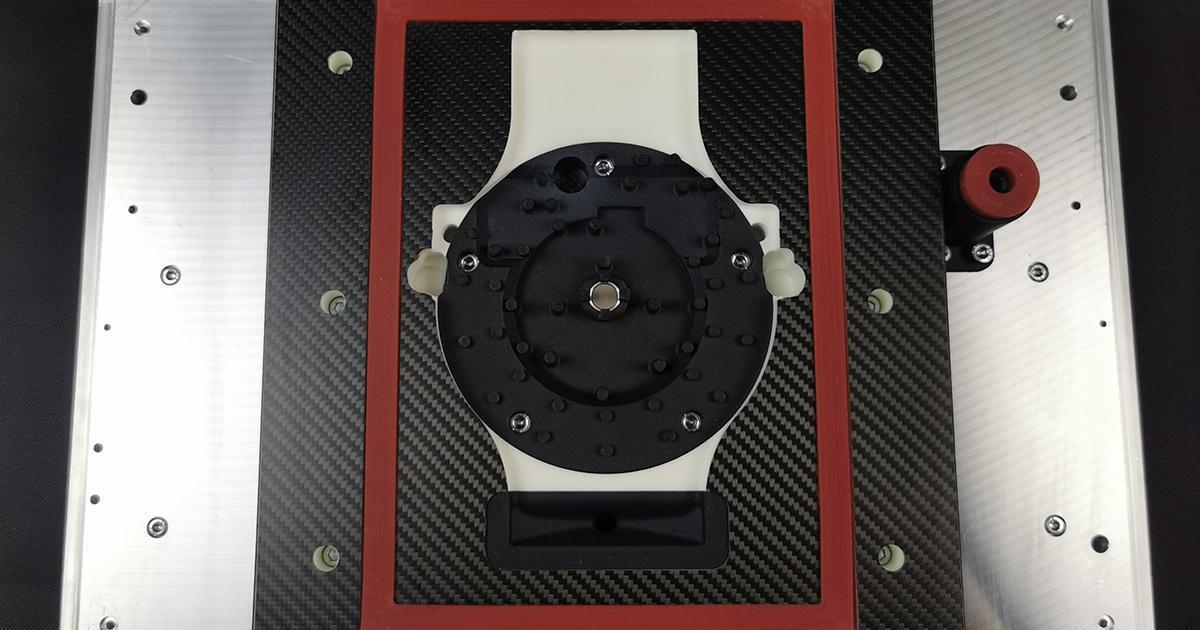

This design includes a manually operated fixture and is used for the functional test (FCT) of a sensor.

A special design beyond any standard - a combination of multi-sided contacting floating connectors, LED detection via sensors (DCA), pneumatic push-button actuation and the use of a camera to read out display indicators.

This project is a product development for testing a wide variety of test assemblies. Together with our customer and in close cooperation with his test requirements, we have developed a test concept that focuses on the highest flexibility in the field…

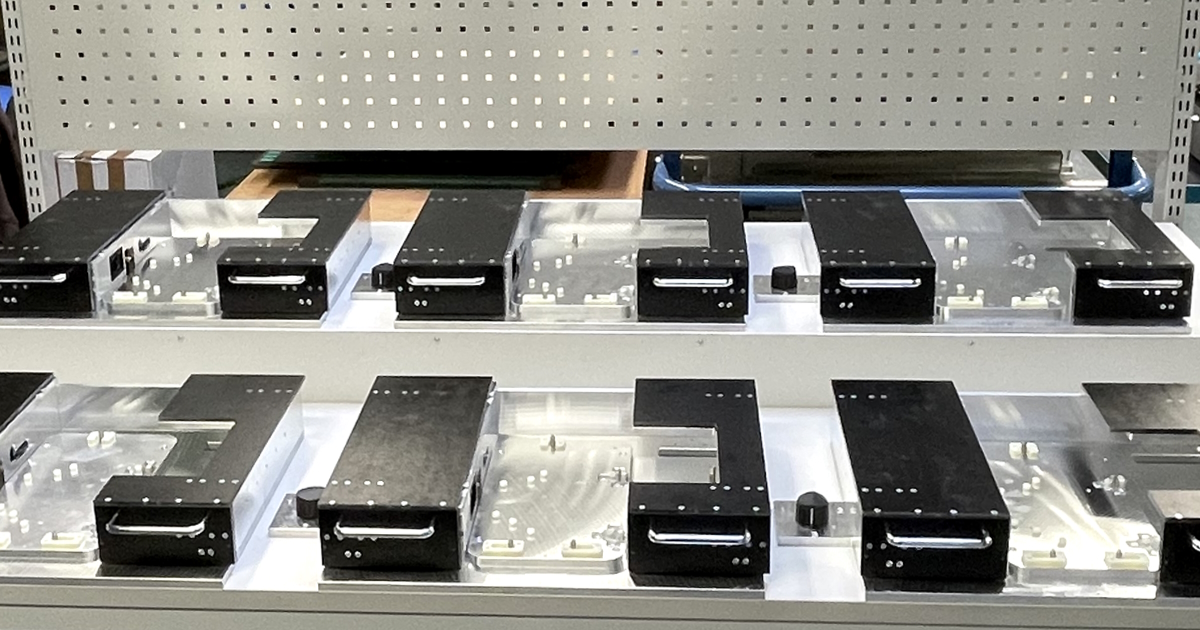

This is a mechanical test fixture for testing cameras. For this reason, the test process takes place in the dark area. This customized design enables the testing of 48 device under test (DUT) at the same time.

This is a test fixture for performing Highly Accelerated Life Tests (HALT) or Highly Accelerated Stress Screenings (HASS). As a qualitative test method, it is designed to expose electronic and electromechanical assemblies to an accelerated aging…