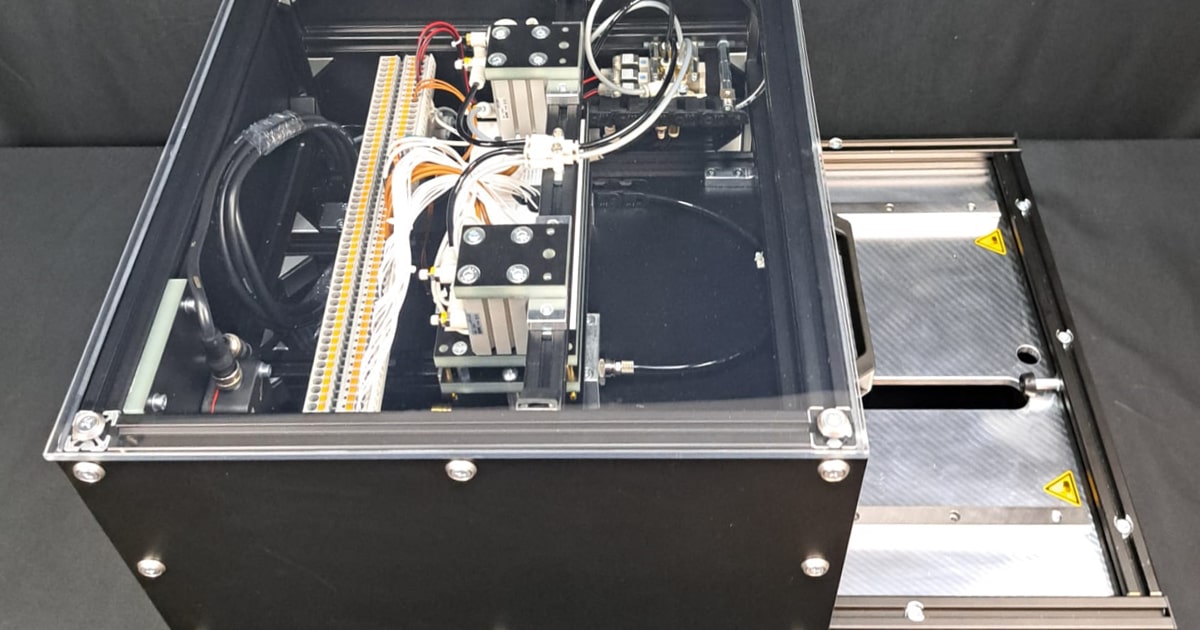

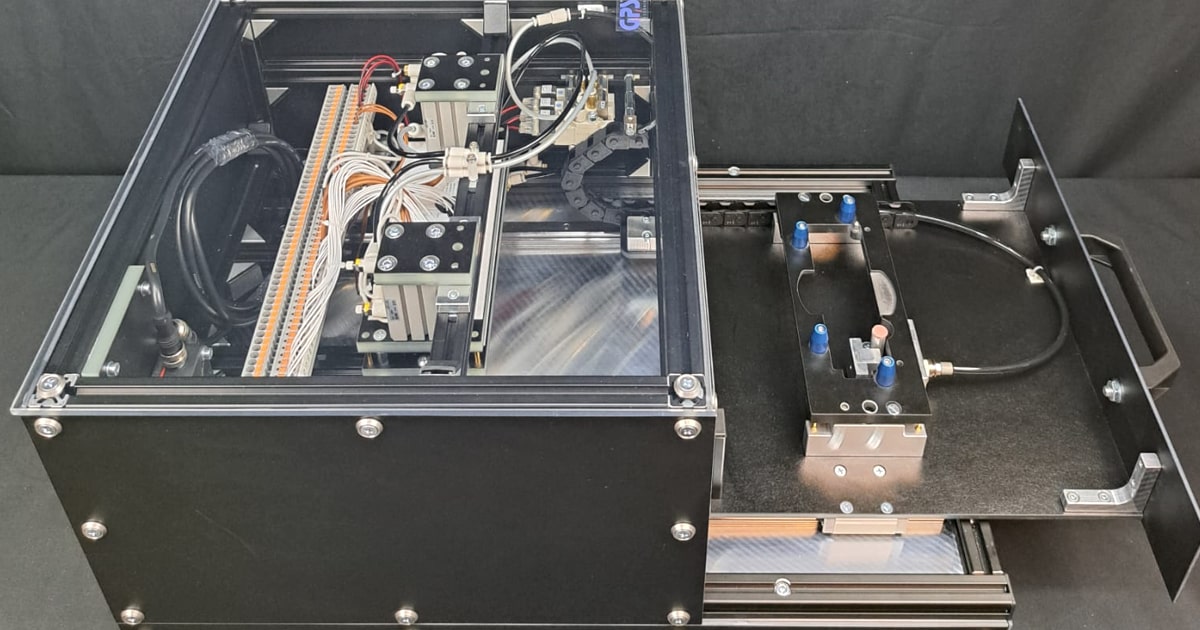

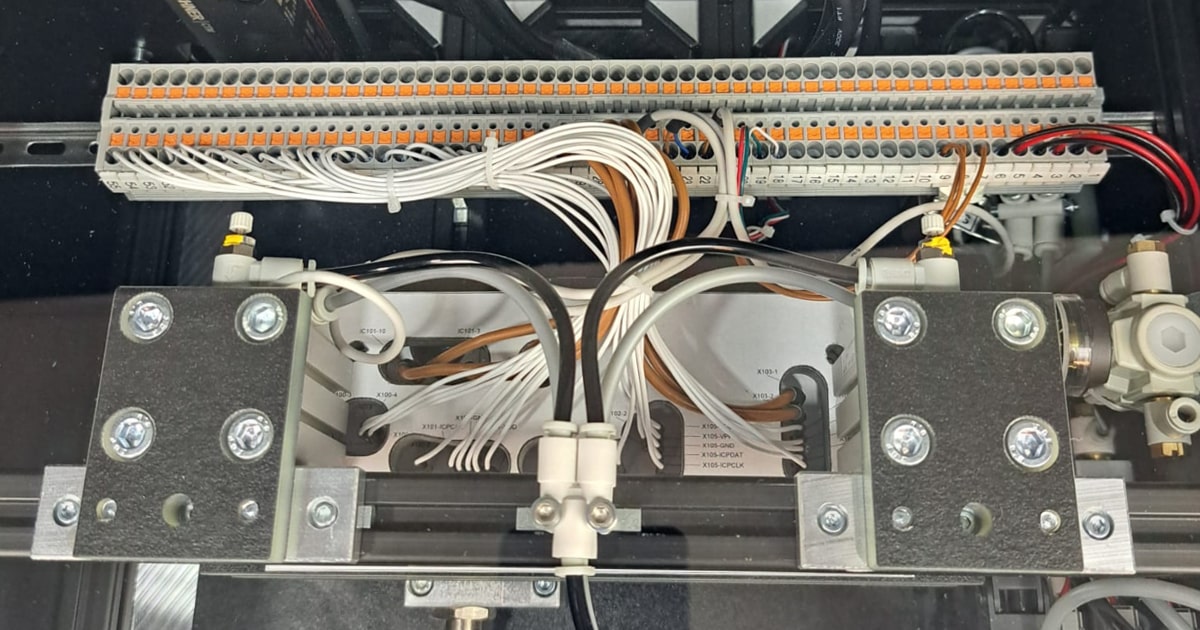

Test fixture incl. temperature sensor and cooling system

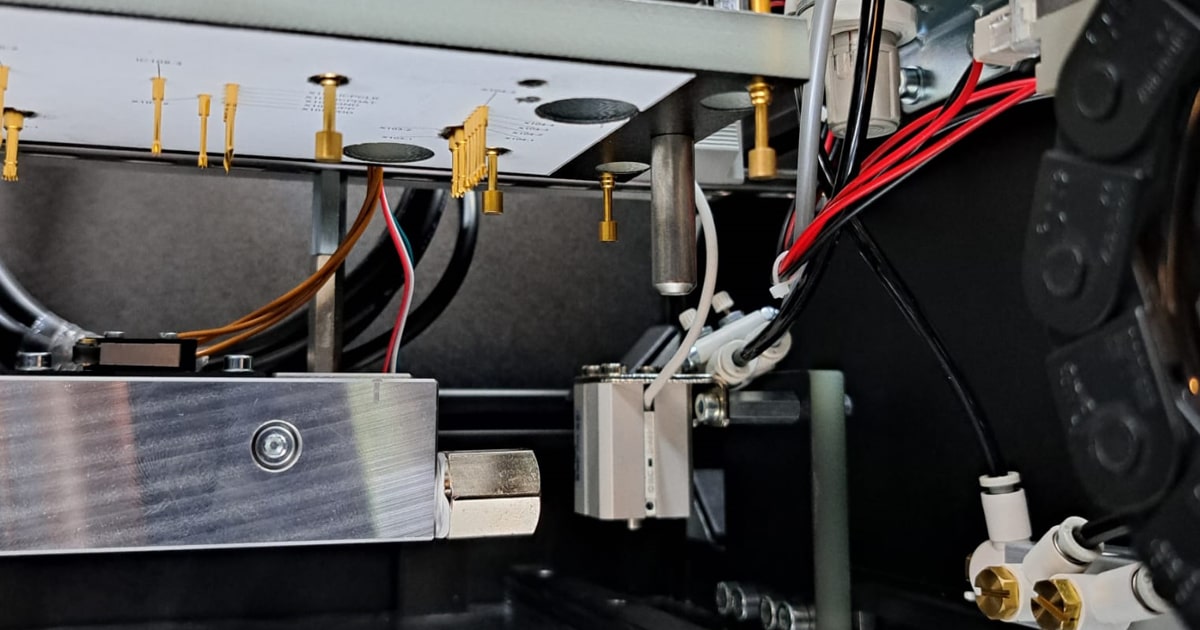

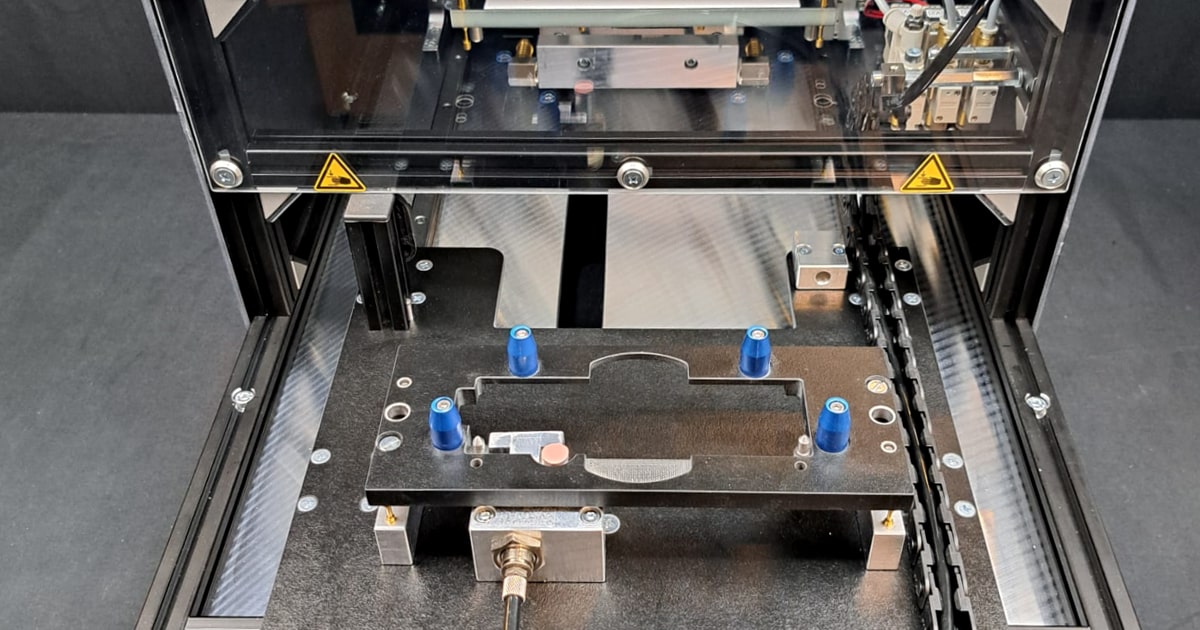

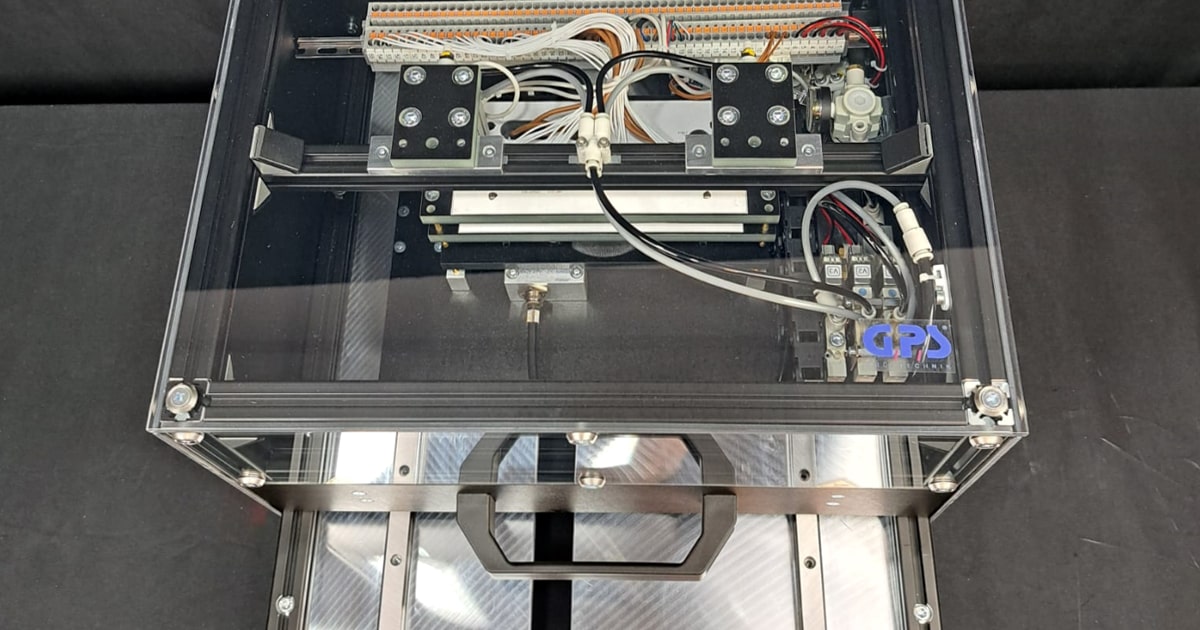

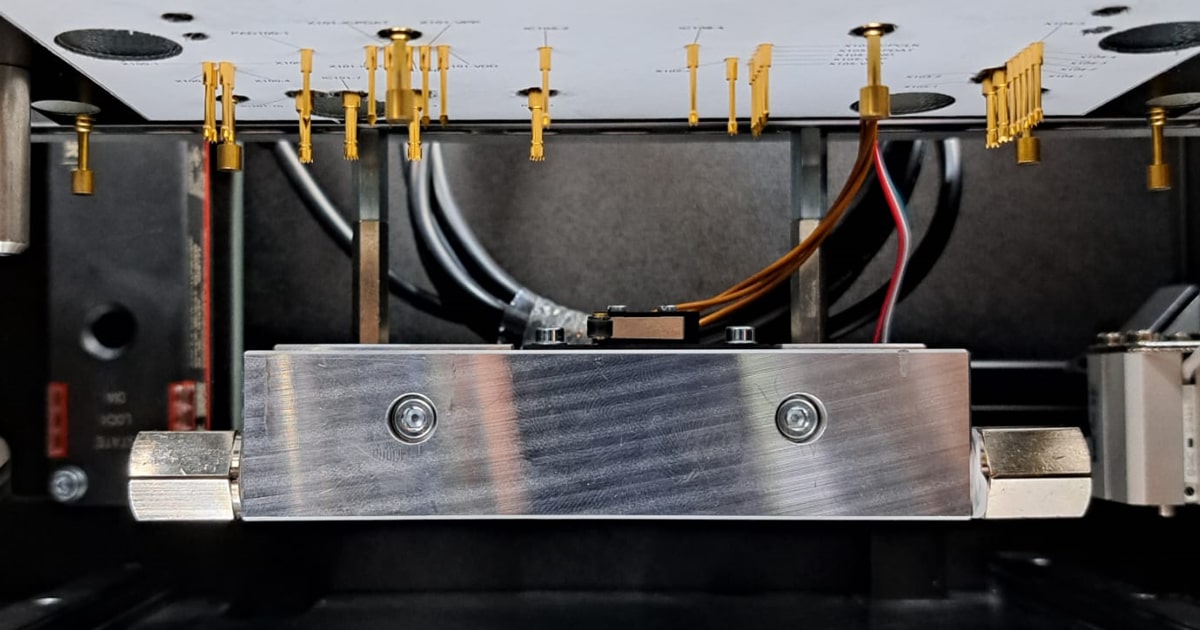

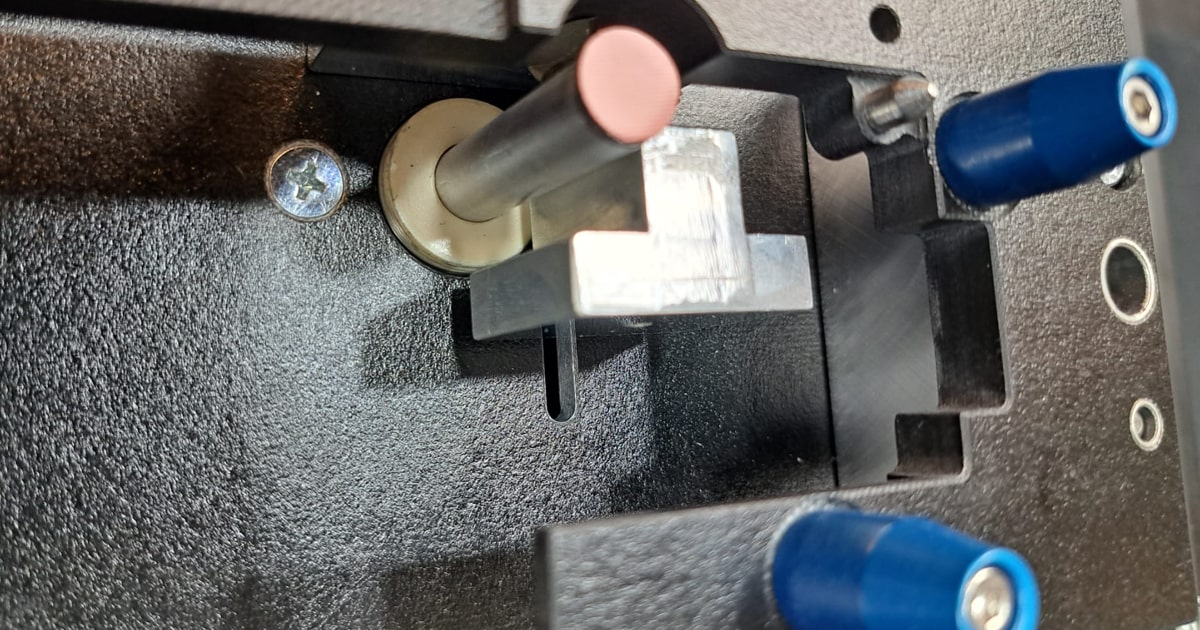

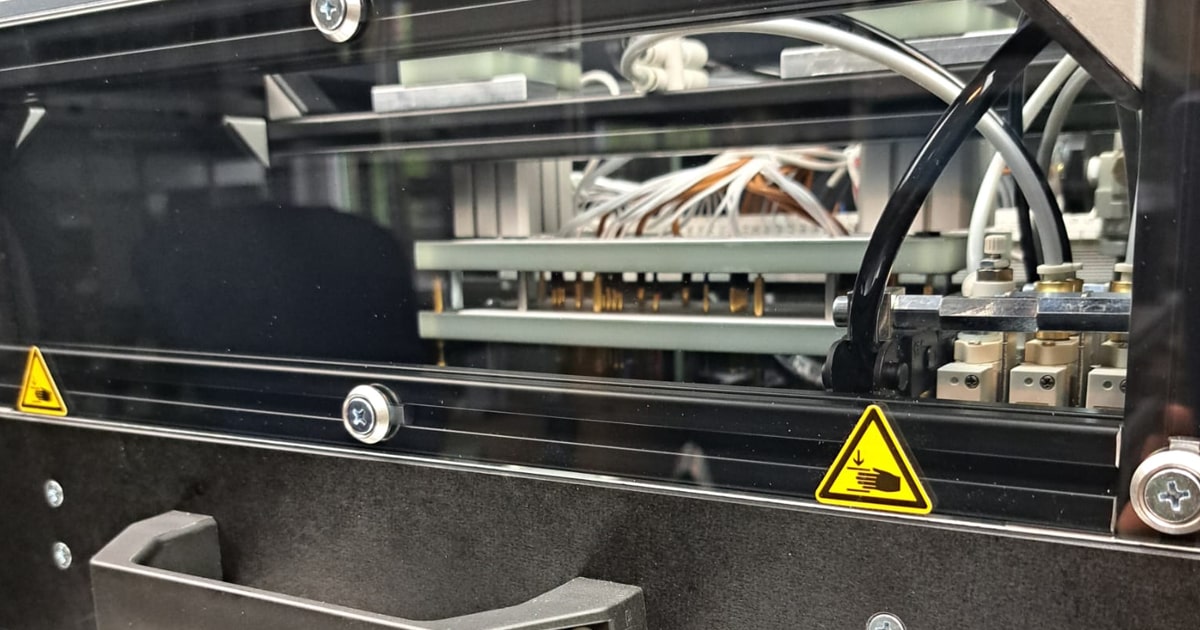

Customized design - electro-pneumatic fixture

The design and implementation isn´t a standard solution. The test fixture has been developed and designed to meet specific customer specifications and requirements.

The test device is placed on a mobile work table in combination with a computer provided by the customer and fitted into the existing production lines. The fct test fixture meets the following extensive requirements:

- Device with throttleable pneumatic cylinder for locking and pressing on

- Automatic locking and unlocking

- Low-noise test process

- Spring-supported pressing of the heating element onto the temperature sensor

- Pneumatic pressing against the cooling surface

- Pneumatic contacting of the test fixture with the DUT

- Process programming via two in-circuit programming devices

- Matching of test specimen to software

- Voltage and current measurement

- Query error states

- Ergonomic insertion of the DUTs

- Oscillator calibration of the DUT

- Position monitoring of the moving parts using appropriate limit switches

- Installation of 24V DC electrically controllable pneumatic valves

Facts

Special feature: Incl. temperature sensor and cooling system

Fixture type: Electro-pneumatic special design

Test type: FCT