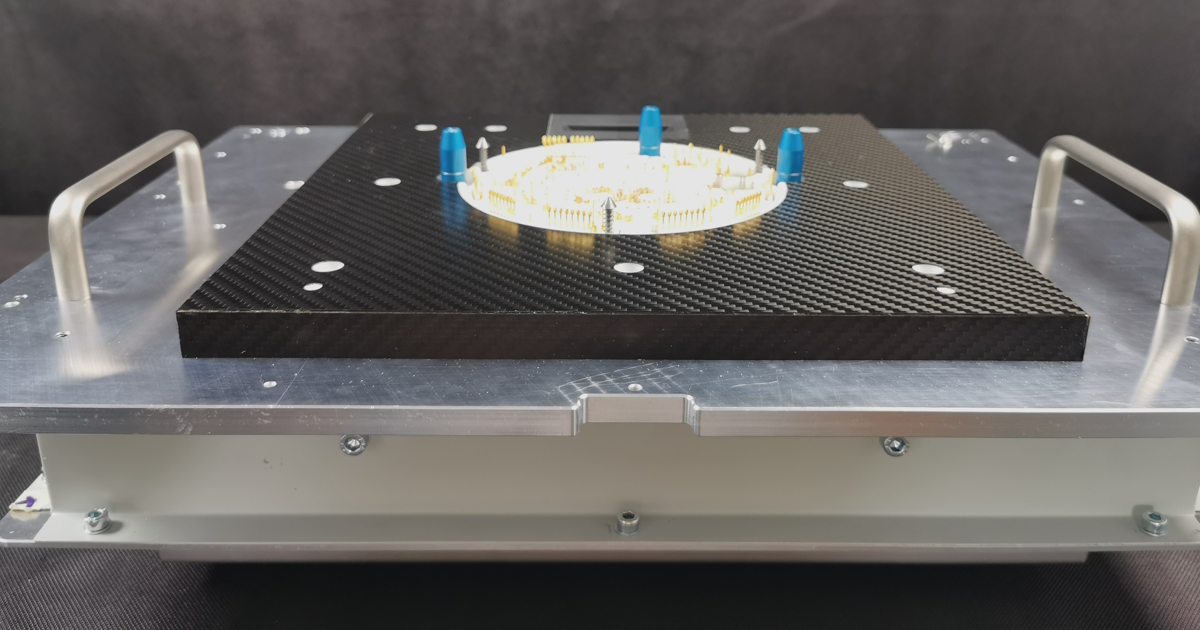

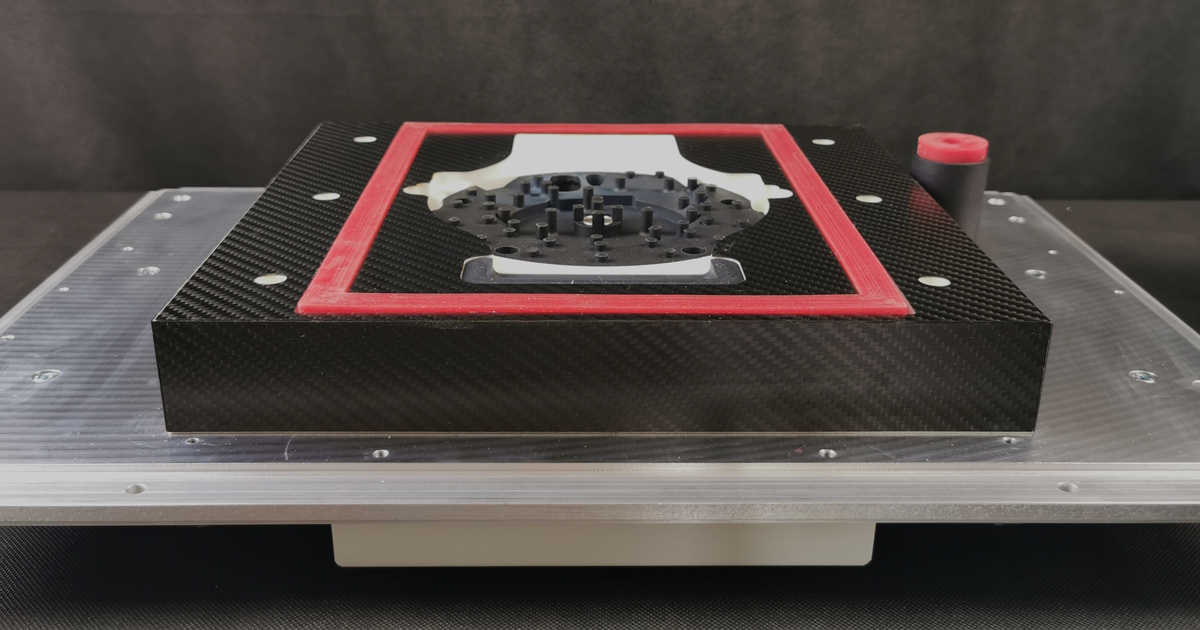

Thermo fixture

Testing at extreme temperatures

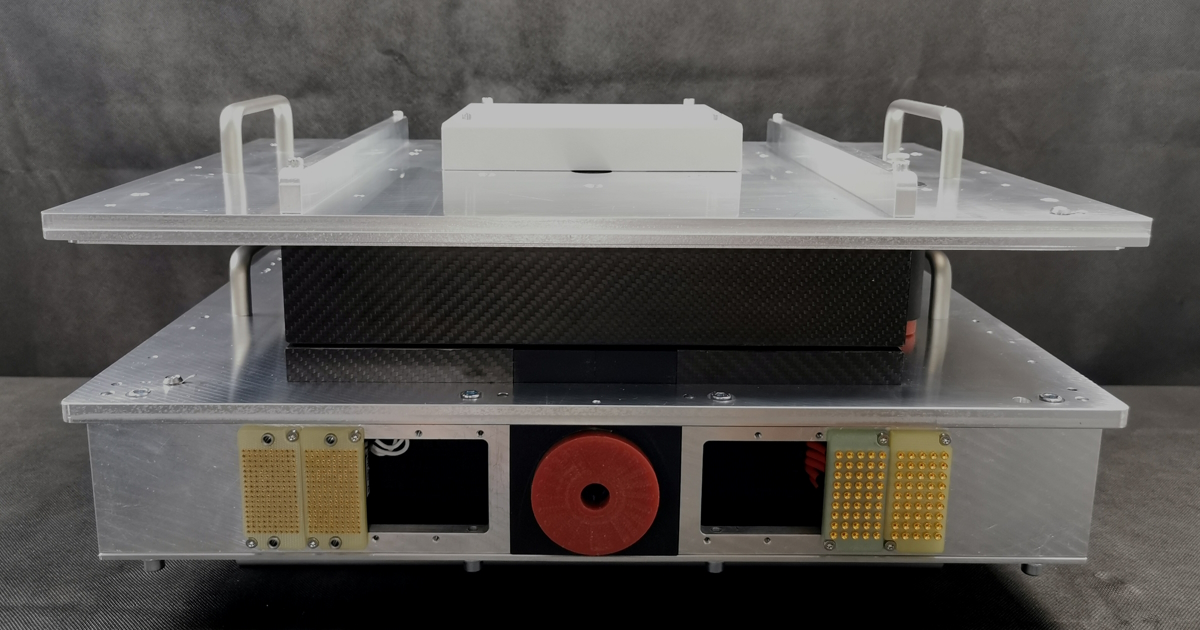

This is a test fixture for performing Highly Accelerated Life Tests (HALT) or Highly Accelerated Stress Screenings (HASS). As a qualitative test method, it is designed to expose electronic and electromechanical assemblies to an accelerated aging process. In this way, weak or defective points can be identified as early as the product development phase.

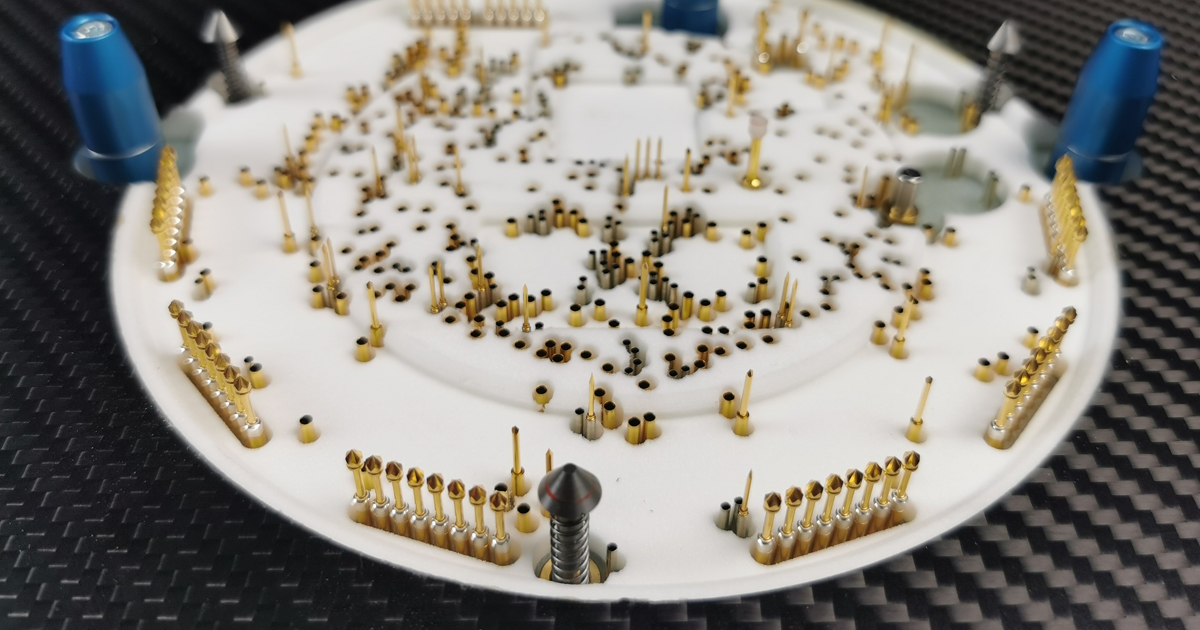

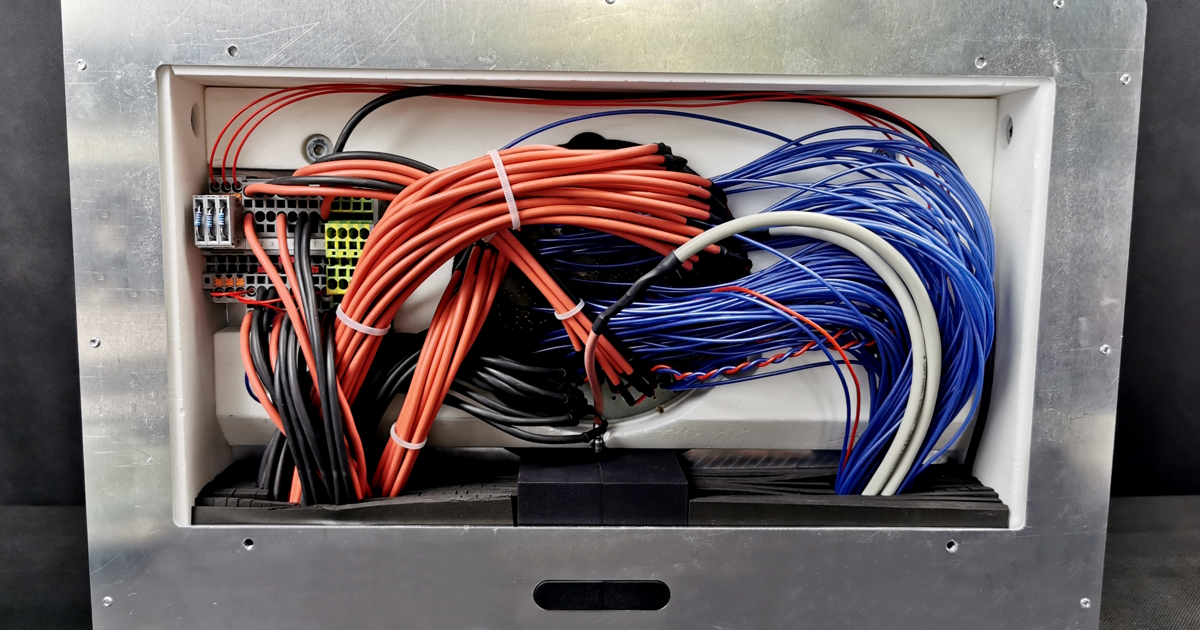

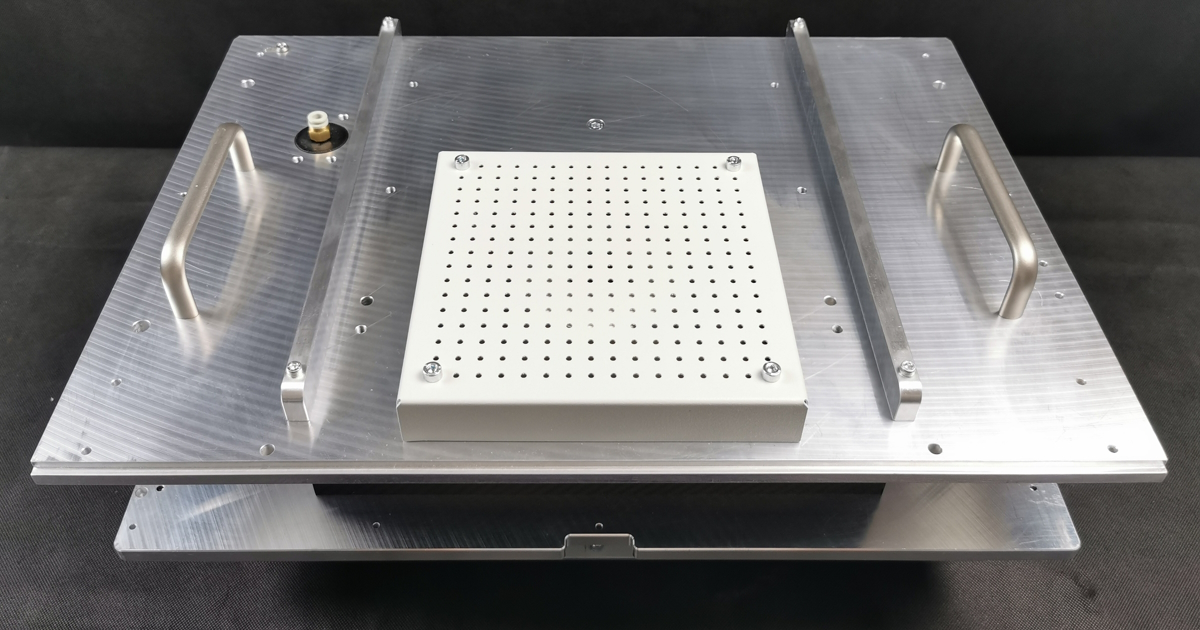

The test procedure takes place in a special thermal test fixture, which we developed and produced together with the test system manufacturer Konrad GmbH.

During the test procedure, the test specimen is exposed to extreme temperatures, which range from -40°C to +85°C as standard. Deviating temperature ranges are also possible at this point. The temperature change takes place at very short intervals, lasting only a few seconds, in order to simulate an accelerated aging process. The entire test procedure is carried out entirely without a climatic chamber. The thermally insulated test fixture is filled with appropriately tempered air via a thermal device. The fixture is designed in such a way that the air streams circulate around the board under test to ensure uniform temperatures from all sides.

Facts

- Special feature: Thermal test

- Test type: HALT / HASS

"Quality and professionalism are written in capital letters at GPS Prüftechnik. We are highly satisfied with the implementation of our project. Cooperation, communication and ultimately the test fixture itself have convinced us completely."